As an indispensable material in the production process of enterprises, measuring tools play an indispensable role in product quality control. The quality of measuring tool management directly determines the quality management level of enterprises. For most enterprises, the measuring tools adopt manual management or excel management, which is a blind area beyond the control of ERP and MES. The management level and efficiency are low, and professional management tools are urgently needed to improve.

1、 Characteristics of measuring tool management

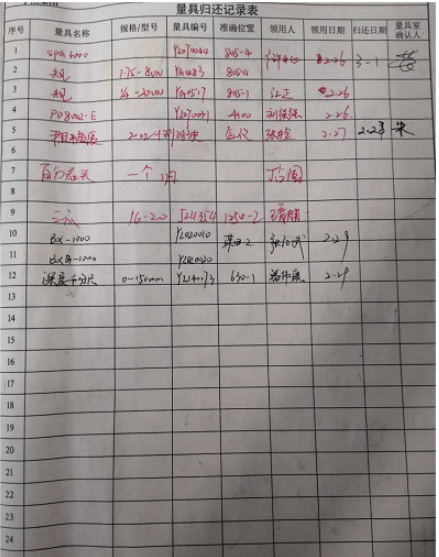

1.1 frequent collection and registration is troublesome, records are missing, sizes are different, and it is difficult to store them uniformly;

1.2 forget to return, difficult to trace and often lost;

1.3 there are a large number of measuring tools, forgetting calibration and using them out of date, resulting in quality risk

1.4 handwritten labels are annoying, stored in many places, difficult to judge, and management is out of control

2、 Typical problems

2.1 repeated collection and return is difficult to count and trace and is often lost

2.2 the storage is chaotic, the inventory is often wrong, and the accounts are often inconsistent with the actual situation

2.3 there are many measuring tools without calibration reminder, and the calibration is often forgotten, resulting in quality risk

2.4 the loss of measuring tools will affect the production, and the unit price of measuring tools is high

3、 Brief description of hangruicheng solution

Focusing on improving the management and control level of measuring tools, the company has established a complete set of management system in combination with the process of measuring tool management, focusing on the following management ideas:

3.1 key improvements:

1. Solve the core pain points of frequent handwritten registration forms, which are easy to make mistakes, difficult to implement and difficult to count;

2. Solve the problem of Excel management, which is difficult to remind, send reports, and record the pain points of scrapping and verification costs;

3. Customized according to the use process of measuring tools, with 100% customer satisfaction.

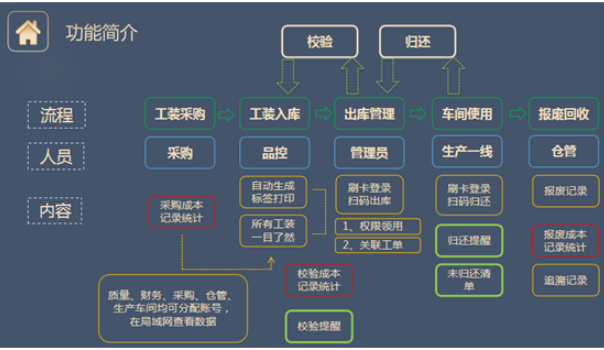

3.2 software function modules: collection and return module, check in and out module, inventory and destination query module, cost statistics module and check reminder module:

4、 Introduction to scheme implementation

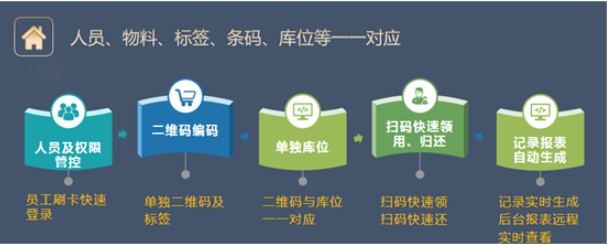

4.1 gauge code and warehouse location code

1. When warehousing, the system automatically generates serial number and QR code

It can be in the form of two-dimensional code label and pasted on the surface of the measuring tool or packaging box, or laser two-dimensional code can be used:

4.2 system deployment: the software is deployed in the measuring tool room (manual mode) + the intelligent cabinet is deployed in the workshop (unmanned mode), the data is unified, and the records and reports can be viewed on the LAN at any time

The original shelves are used for storage, and the number of each storage location is included in the system control.

When the employee swipes the card, the administrator will automatically generate the record of swiping the card. When returning, scan the code to return directly and prompt the location information.

The smart cabinet can be selected according to the size of measuring tools. For details, please contact the pre-sales engineer of hangruicheng

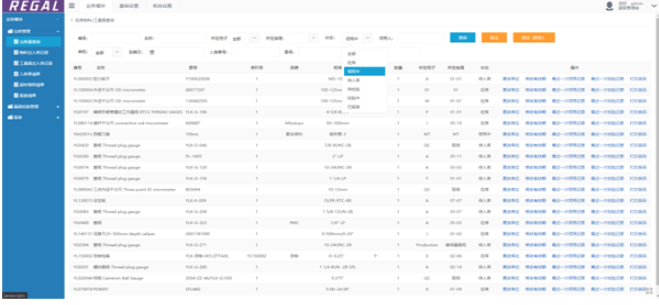

4.4 software main interface

4.5 partial report display

Inventory list, last collection query (destination tracking), warehouse location query, status query, outstanding query, collection return record, preliminary statistics and maintenance reminder

5、 Features and advantages of the scheme

5.1 all measuring tools from warehousing to scrapping, all circulation processes and expenses are automatically recorded and controlled in the whole process, and reports are automatically generated and can be viewed in real time;

5.2 connect with ERP and MES, collect materials according to department, product and other dimensions, and make corresponding analysis reports;

5.3 remind the whereabouts of measuring tools to greatly reduce the loss of measuring tools;

5.4 greatly improve the management level, greatly save the inventory time, greatly reduce the labor consumption, greatly optimize the inventory level, and greatly improve the product quality and efficiency

6、 Feedback on some customer cases

6.1 customer status

Suzhou * * fluid Co., Ltd. mainly orders a variety of small batches, with 35 large machine tools. All products are exported. Moreover, the processed parts and components for the drilling platform require very high precision. Therefore, the measuring tools are mainly imported, and the unit price is very high, ranging from thousands to more than 100000.

There are three departments of incoming materials, production and final inspection that need to be borrowed, and more than 100 people use them. In addition, the meter needs to be adjusted during partial collection;

Originally, it was controlled by manual recording and excel search. There were three people on the day shift, one for table adjustment, one for receiving and returning, one for maintaining and writing labels, and one person on the night shift.

6.2 core issues

1. Collect and return hundreds of times a day, and the data records are incomplete and cannot be counted;

2. Multiple storage, missing records, unable to inventory, often missing calibration;

3. There is only one person on the evening shift, and the registration record is often not written;

As a result, there are often abnormal losses, loss of measuring tools, huge losses, affecting the stability of production and team, and serious loss of personnel.

6.3 improvement plan of Ruihang

Hangruicheng intelligent measuring tool management scheme is adopted, with the whole process code printing management, code scanning in and out of the warehouse, automatic reminder and automatic statistical write off.

Four sets of smart cabinets are deployed in the workshop and placed next to the production line to greatly improve the efficiency of collection and return and greatly reduce the collection time.

6.4 improvement effect

|

15050151202 Free service hotline |

|

Follow us Please scan the official account |

Copyright © HRC Automation(Suzhou)Co.,Ltd 备案号:苏ICP备19026496号